BIG BAG

BIG BAG

At present, BIG BAGs have become the most popular large-size packages on the market. A very easy way to design such a package allows constructing any bag that can be applied in any field of industry.

Big bags are made of polypropylene fabrics (PP). Fabrics can be uncoated and laminated (coated, non-breathable). They can be divided into flat and round-woven. PP fabrics are UV stabilized and fully recyclable, which directly translates into environmental protection and cost savings.

The most common big bag structures include single-trip, double-trip and four-trip structures.

Big bags can also be equipped with LDPE foil inserts.

They may be provided with an internal structure (stabilizer) thanks to which the bags are not deformed after charge.

On the market, big bags are also divided due to their electrical conductivity, and these are type B and type C bags. This type of packages are used for transport of electrostatic materials.

Several possible technical solutions in bags:

Charge part:

|

|

|

|

|

| open top with a flap | Galen charge valve | open top | charge valve | apron |

Charge part:

|

|

|

|

| straight bottom | chute valve | Galen chute valve | apron with curtains |

|

|

|

| conical bottom | chute with a flap | Rosetta chute valve |

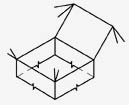

Single-trip, single-loop, single-handle big bags

Single- and double-trip bags are less complex and more economical compared to four-trip bags. They are made from tubular materials, sleeves (round-woven fabric) to provide greater resistance to lateral tearing of the fabric. Trip wrappers can be made from fabrics having different colours, which makes it very easy to distinguish, for example, the contents of the bag. The most commonly used structure is usually the one without coating with an open top and PE liner inside. Base designs vary greatly depending on their application. The bottom may be a square, a star or one seam.

Single- and double-trip bags are less complex and more economical compared to four-trip bags. They are made from tubular materials, sleeves (round-woven fabric) to provide greater resistance to lateral tearing of the fabric. Trip wrappers can be made from fabrics having different colours, which makes it very easy to distinguish, for example, the contents of the bag. The most commonly used structure is usually the one without coating with an open top and PE liner inside. Base designs vary greatly depending on their application. The bottom may be a square, a star or one seam.

Chute holes may be used but then the bottom is sewn in a square. For manual application, bag fillings are packed on pallets of 500 pieces. However, bags can be wound on rolls, the so-called bag rolling, that will be used in automatic filling stations.

This type of package - single-trip, single-loop, single-handle big bags is the most often used solution in the chemical and fertilizing industries.

The charge weight in this type of package is: 500kg, 600kg, 1000kg.

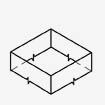

Double-trip, double-loop, double-handle big bags

Single- and double-trip bags are less complex and more economical compared to four-trip bags. They are made from tubular materials, sleeves (round-woven fabric) to provide greater resistance to lateral tearing of the fabric. Trip wrappers can be made from fabrics having different colours, which makes it very easy to distinguish, for example, the contents of the bag. The most commonly used structure is usually the one without coating with an open top and PE liner inside. Base designs vary greatly depending on their application. The bottom may be a square, a star or one seam. Chute holes may be used but then the bottom is sewn in a square. For manual application, bag fillings are packed on pallets of 500 pieces. However, bags can be wound on rolls, the so-called bag rolling, that will be used in automatic filling stations.

Single- and double-trip bags are less complex and more economical compared to four-trip bags. They are made from tubular materials, sleeves (round-woven fabric) to provide greater resistance to lateral tearing of the fabric. Trip wrappers can be made from fabrics having different colours, which makes it very easy to distinguish, for example, the contents of the bag. The most commonly used structure is usually the one without coating with an open top and PE liner inside. Base designs vary greatly depending on their application. The bottom may be a square, a star or one seam. Chute holes may be used but then the bottom is sewn in a square. For manual application, bag fillings are packed on pallets of 500 pieces. However, bags can be wound on rolls, the so-called bag rolling, that will be used in automatic filling stations.

This type of package - single-trip, single-loop, single-handle big bags is the most often used solution in the chemical and fertilizing industries.

The charge weight in this type of package is: 500kg, 600kg, 1000kg.

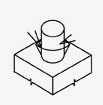

Four-trip, four-handle big bag.

Bags are one of the most cost-effective and ideal types of packs for shipment and storage of dry loose products. Big bags are either tubular or flat polypropylene (PP) fabrics.

Bags are one of the most cost-effective and ideal types of packs for shipment and storage of dry loose products. Big bags are either tubular or flat polypropylene (PP) fabrics.

These fabrics may be either coated or uncoated and are different in weights depending on the requirements of the safe working load (SWL) and the safety factor (SF).

The bag can be as simple as an open top with a flat bottom commonly used in construction or as a high tech unit manufactured in a clean production room environment to be used for the food/pharmaceutical industry.

First of all, each bag is manufactured to meet the requirements of a particular customer.

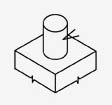

Q-bag (big bag)

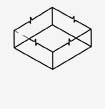

The Q BigBag design is built using an internal partition that helps to maintain the cube-shaped form of the bag after filling.

These partitions are made to allow material to flow in the corners of the bag.

Due to the design and the cubic shape of the Q bag, it requires less space and reduces transport costs by up to 30% compared to the standard big bag.

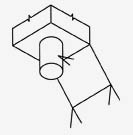

Four-trip, four-loop, four-handle, ventilated big bags.

Bags for potatoes, vegetables are produced from ventilated (PP) fabric.

These fabrics are specially designed to allow for free flow of air through the fabric into the bag.

The most common closure is the so-called raschel apron that allows for free breathing of potatoes and vegetables, which is a condition for good storage and transport.